|

|

|

Editorial

Recognition of the need for a Circular Economy clearly unites many stakeholders in Europe, but as the debate continues on how to get there, the part that steel can play gathers clarity and momentum.

Steel is quoted as an example for resource efficiency in the European Environment Agency in its SOER 2015 report. The benefits of multiple recycling and permanent materials are acknowledged by the European Economic and Social Committee in their opinion piece on the circular economy.

It is becoming clear that whilst recycling is already good, “Recycles Forever” is what the world needs now and our new LCI dataset shows how steel is well placed to demonstrate measurable sustainability in a true life cycle approach.

Finally the steel beverage can celebrates its 80th anniversary this year. Long live the can and the sustainability of steel!

Patricia Mobbs, Editor |

|

|

|

|

|

|

|

Inside Brussels - Alexander Mohr on steel for packaging in European policy discussions |

|

|

|

|

|

The Circular Economy Package presented by previous EU Environment Commissioner Janez Potočnik was officially withdrawn last February but the Commission Vice-President Timmermans and current Environment Commissioner Karmenu Vella have both confirmed that a new package, due after the summer, will include binding recycling targets.

It has to be said that since the new commission announced its decision to withdraw the Circular Economy Package back in December, intense pressure has mounted from multiple sides. Protests resounded from amongst the European Parliament and EU environment ministers, whilst industry partners and NGO’s put pen to paper and delivered reports labelling the decision as a “scandal” and calling for an improved bill, fast.

Even the recent SOER 2015 report (“The European environment — state and outlook 2015”) edited by the European Environment Agency confirms how waste management is improving but Europe remains far from a circular economy and calls for radical changes.

Interestingly for APEAL, the same report uses the example of steel to demonstrate how recycling can help Europe meet a substantial proportion of its raw material demand. It’s certainly good news for us at APEAL to see the efforts of our industry and partners recognised in this way. More importantly, we are encouraged that the report underlines the opportunities to improve resource efficiency across the EU and we are confident that this will input the new Circular Economy package expected later this year. |

|

|

|

|

|

|

|

|

|

APEAL releases new LCI dataset for tinplate

|

|

|

|

|

APEAL’s Life Cycle Inventory (LCI) dataset for tinplate aims to provide a complete environmental profile of steel packaging that our customers, particularly in the fast-moving consumer goods industry, can use to calculate the complete environmental profile of their products.

In a world of finite resources where we must move towards a circular economy model to optimise resource efficiency, life cycle thinking becomes a key requirement for all manufacturing decisions going forward. As a tool, life cycle assessment (LCA) enables us to measure the holistic environmental performance of a product at each stage in its lifecycle, providing a measure which can be used to compare the environmental sustainability of similar products.

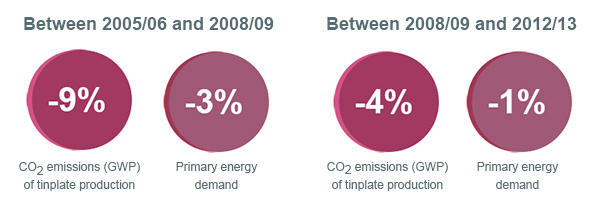

Our latest LCI dataset for tinplate packaging gives the most accurate and up to date environmental profile of tinplate as a packaging material and shows the continuous improvements in environmental performance made by our industry, most notably a further 4% decrease in Global Warming Potential (GWP), expressed in carbon emissions equivalent, and an extra 1% decrease in primary energy demand.

This study included 2 more sites compared with the previous dataset, so the dataset now covers data from 11 European sites operated by 4 companies from the production year 2012/2013. The study was again carried out in line with the WorldSteel Association LCA methodology.

The new dataset will shortly become publicly available on the European Reference Life Cycle Database (ELCD), accessible from our website http://www.apeal.org/en/Life-cycle-thinking/lcas. The ELCD is managed by the European Platform in Life Cycle Assessment and allows simple web-based access to high quality life-cycle data from reliable sources.

“Publication of APEAL’s LCI dataset on this platform confirms it as the dataset of reference for steel packaging across Europe” said Alexander Mohr, secretary general of APEAL. “Our ultimate objective is to ensure this is used as the reference set for steel for packaging production in Europe, for both science and industry.” |

|

|

|

|

|

|

|

|

|

|

“The revision of the waste package now offers a unique opportunity to embrace the principle of multiple recycling for permanent materials.” |

|

European Economic and Social Committee (EESOC), December 2014 |

|

|

|

|

|

|

|

|

The beverage can celebrates 80 years |

|

|

|

|

|

On 24 January 1935 a US-based brewery became the first in the world to sell beer in a steel can. It’s now 80 years later and the beverage can has become a modern phenomenon on a global scale.

Beverage cans maintain a certain number of advantages over other packaging solutions. Cans are easy to brand, easy to fill at high speeds, extremely rigid and tough, both on filling lines and at the point of sale, as well as 100% recyclable.

The beverage can attracts all ages due to:

- Style: For consumers, cans are convenient, robust, light, compact, easy to open, and the fastest packaging format to chill. For brands they offer more room to display art and graphics;

- Taste: Contents are protected from water, air and light, which can affect a product’s taste and deteriorate the ingredients it contains. Cans are ideal for carbonated beverages;

- Sustainability: 100% recyclable, compact, light stackable for transport and storage efficiency, delivering increased convenience throughout the supply chain.

As such, demand for beverage cans has shown steady growth of 4% per year on average in Europe for the past 10 years, with the European market currently estimated at 63 billion cans (www.bcme.org).

The original beverage can was made from steel and it dominated the market until the arrival of aluminium as an alternative material in the 1950’s. The aluminium beverage can claimed a weight advantage over steel. However steel cans have become much lighter over time, with a standard 33cl steel beverage that weighed 100g in 1935 now weighing about 20g today, with no loss of functionality. Steel cans are the strongest and most robust material on the filling line and in the supply chain. Steel cans are more recycled too, with 74% of steel packaging recycled in Europe in 2012.

And as our life cycle approach develops an ever more precise picture of the global footprint of tinplate, the sustainability advantage of steel may well push brand owners and fillers to “Take a Fresh Look” at the steel beverage can. |

|

|

|

|

|

|

|

|

|

|

|

|

The amount of energy required to produce a tonne of crude steel has been reduced by about 60% since 1960 in most of the top steel producing countries

|

|

|

|

|

|

|

|

#steeltalks on sustainability |

|

|

|

|

|

Why is steel the competitive material of choice in a sustainable world? That was the question put to our industry during January’s #steeltalks Twitter debate, hosted by WorldSteel Association.

Business leaders, steel professionals and leading academics were amongst the 440 who took part, asking questions and offering opinions around steel and sustainability.

The key conversations centred on recycling and Life Cycle Assessment, indicative of the development of the LCA tool within our industry. What our industry has already done, and what is it still doing, to reduce CO2 emissions gathered a lot of interest too.

Steel research trends and development were key for a number of participants, focused on recent improvements and the kinds of innovations necessary to modernise our economies further.

Steel for packaging responded directly to questions about the current recycling rate.

The innovative nature and adaptability of the industry was evident throughout the debate. The economic value of steel was also widely discussed. The global steel industry employs more than eight million people and spends over €10.5 billion a year on improving manufacturing processes, and developing new products and innovative materials.

But the debate actually says a lot more about the industry. It is evidence of a modern approach to communication and a transparency that is not always present among material manufacturers.

The positivity on show when looking back over the tweets in the debate should fill everyone involved with the steel industry with optimism. The steel industry is showing that it can adapt and innovate. It is a vibrant sector and custodian of a truly valuable material resource, both in terms of its economic influence and its environmental benefits. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enlarge image

Steel packaging has an integral part to play in the global circular economy, and life cycle thinking is the way forward. Read more about the role of steel in the circular economy here. |

|

|

|

|

|

|

|

|

|

|

|

FoodProductionDaily - January

Dr Roeske gives his first interview as APEAL President and discusses market growth in cans and the role of legislation in reaching higher recycling inside a circular economy.

|

|

|

|

Can Tech International - April

Alexander Mohr discusses the impact of the withdrawal of the Circular Economy Package (CEP) on the steel for packaging sector, as well as the role steel will play in the drive for sustainability, food security and reducing food waste..

|

|

|

|

|

|

|

|

|

|

|

|

| Contact us |

|

|

|

|

APEAL

The Association of European Producers of Steel for Packaging

Avenue Ariane 5

BE-1200 Brussels | Belgium

Tel +32 2 537 9151 | Fax +32 2 535 7200

|

|

|

|

|

|

|

|

|

|

|

© 2024 APEAL, All rights reserved

|

|

|